Views: 222 Author: Loretta Publish Time: 06-27-2025 Origin: Site

Content Menu

● Introduction to Swimwear Lining Fabric

● Why Is Swimwear Lining Important?

● Common Fabrics Used for Swimwear Lining

>> 4. Power Net

● Technical Features to Consider in Swimwear Lining Fabric

● Types of Swimwear Lining by Coverage

● How to Choose the Right Swimwear Lining Fabric for OEM Production

● Practical Tips for Sewing Swimwear Lining

● Enhancing Swimwear Performance with Advanced Linings

● FAQ

>> 1. What is the most common fabric used for swimwear lining?

>> 2. Why is swimwear lining necessary?

>> 3. Can I use the same fabric for both the outer layer and lining?

>> 4. What is power mesh and when is it used?

>> 5. How do I sew swimwear lining to ensure durability?

Swimwear lining plays a crucial role in the construction, comfort, and durability of swimsuits. For swimwear brands, wholesalers, and manufacturers providing OEM services, understanding the best fabrics for swimwear lining is essential to deliver high-quality products that meet international standards and customer expectations. This comprehensive article explores the types of fabrics used for swimwear lining, their properties, benefits, and practical tips for choosing and using them in swimwear production. Visuals and videos illustrating fabric characteristics and sewing techniques are integrated throughout to enhance understanding.

Swimwear lining is the inner layer of fabric sewn inside swimsuits to provide coverage, support, and comfort. It prevents transparency when the swimsuit is wet, protects the outer fabric from wear and tear, and enhances the garment's fit and structure. The lining fabric must be lightweight, breathable, stretchy, and resistant to chlorine, saltwater, and UV rays.

- Coverage and Modesty: Lining prevents see-through issues when the swimsuit gets wet, providing confidence and modesty.

- Support and Structure: It offers additional support, especially in the bust and tummy areas, and helps maintain the swimsuit's shape.

- Comfort: The lining fabric is soft and smooth against the skin, reducing irritation and chafing.

- Durability: It protects the swimsuit's outer fabric from damage caused by chlorine, saltwater, and sun exposure.

- Fit: Lining ensures a snug and secure fit that moves comfortably with the body.

- Composition: Typically 80-90% nylon and 10-20% spandex.

- Properties: Soft, lightweight, excellent stretch and recovery, quick-drying.

- Benefits: Comfortable against the skin, smooth texture, and flexible fit.

- Drawbacks: Less resistant to chlorine and UV rays; may fade or lose shape over time.

- Use: Popular for fashion swimwear, bikinis, and one-piece suits.

Nylon-spandex blends are favored for their luxurious feel and excellent elasticity, making them ideal for swimwear that emphasizes style and comfort. The softness of nylon against the skin enhances the wearer's experience, especially during prolonged use. However, the downside is that nylon can degrade faster when exposed to chlorine and sunlight, so it's best suited for casual or occasional swimwear.

- Composition: Usually 85-90% polyester and 10-15% spandex.

- Properties: Durable, highly resistant to chlorine and UV rays, quick-drying, moisture-wicking.

- Benefits: Maintains color and shape longer, ideal for active and competitive swimwear.

- Drawbacks: Slightly less soft and stretchy than nylon blends; heavier feel.

- Use: Preferred for sports swimsuits, chlorine-resistant swimwear, and long-lasting products.

Polyester-spandex blends have gained popularity for their superior durability and resistance to harsh pool chemicals and sunlight. This makes them the fabric of choice for swimwear designed for frequent use, such as competitive swimsuits or swimwear intended for training. Although polyester is not as soft as nylon, advancements in fabric finishing have improved its comfort significantly.

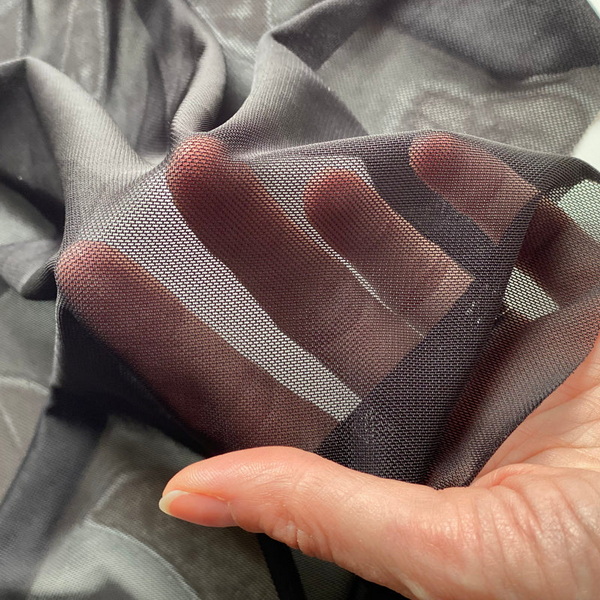

- Composition: Lightweight nylon or polyester mesh with spandex.

- Properties: Breathable, moisture-wicking, moderate compression and support.

- Benefits: Adds support without bulk, quick-drying, breathable.

- Drawbacks: Less coverage, not as durable or stretchy as solid linings.

- Use: Internal panels for shaping, high-waisted bottoms, control swimsuits.

Swim mesh is a specialized lining fabric that provides targeted support and shaping without adding excessive weight or thickness. It is often used in areas where gentle compression is desired, such as tummy control panels or bust support sections. The mesh structure allows for excellent airflow and moisture management, keeping the wearer comfortable.

- Composition: Firm 4-way stretch mesh with high recovery.

- Properties: Strong support, less stretch than power mesh.

- Benefits: Ideal for bust support, waist control, and shelf bra linings.

- Use: Structural support in swimwear designs needing lift and shaping.

Power net is a denser, more supportive mesh fabric used in swimwear to provide firm control and shaping. It is commonly found in the lining of shelf bras, tummy panels, and waistbands where enhanced support is necessary. Its high recovery ensures that the swimsuit maintains its shape even after repeated wear.

When selecting swimwear lining fabric, several technical features must be considered to ensure the final product meets performance and comfort standards:

- Stretchability: The lining should have excellent 4-way stretch to accommodate body movement without losing shape.

- Weight (GSM): The fabric weight typically ranges from 90 to 150 GSM, balancing coverage and lightness.

- Chlorine Resistance: Particularly important for swimwear intended for pool use; polyester blends generally offer superior resistance.

- UV Protection: Some linings provide additional UV protection, which helps protect both the fabric and the wearer's skin.

- Breathability: Good breathability allows moisture to wick away, keeping the skin dry and comfortable.

- Softness: A soft lining prevents irritation and chafing, enhancing wearer comfort.

- Color Fastness: The lining should retain its color after repeated exposure to sun and water.

Swimwear lining can vary based on the amount of coverage it provides, which affects comfort, support, and transparency:

- Fully Lined: The entire swimsuit is lined, offering maximum coverage, modesty, and durability. This is common in one-piece swimsuits and high-end bikinis.

- Partially Lined: Only specific areas, such as the chest or crotch, are lined. This approach balances comfort and breathability with modesty.

- Front Lined: Only the front panel is lined, suitable for those who prefer less fabric on the back, often found in bikini bottoms.

- Self-Lined: The lining is made from the same fabric as the outer layer, allowing reversible wear and a thicker, more durable swimsuit.

OEM swimwear manufacturers must carefully select lining fabrics to meet the needs of their clients and end consumers. Here are key considerations:

1. End-Use Considerations: For fashion swimwear, nylon-spandex blends offer softness and comfort. For active or competitive swimwear, polyester-spandex blends provide durability and chlorine resistance.

2. Fabric Weight: Lightweight linings (90-120 GSM) are suitable for bikinis and light swimwear, while heavier linings (130-150 GSM) offer more support and coverage.

3. Stretch and Recovery: Ensure at least 8-15% spandex content for excellent elasticity and shape retention.

4. Color Matching: Linings come in neutral shades like beige or white for light-colored swimsuits and black for darker ones.

5. Sustainability: Consider recycled polyester or nylon blends for eco-friendly swimwear lines.

6. Supplier Reliability: Choose suppliers offering consistent quality, customization options, and chlorine-resistant fabrics.

Proper sewing techniques are essential to maintain the functionality and longevity of swimwear linings:

- Use a ballpoint or stretch needle (size 75/11 or 80/12) to avoid fabric damage.

- Employ zigzag or stretch stitches for seam flexibility.

- Finish edges with swimwear elastic or fold-over elastic to prevent rolling.

- Pre-wash lining fabric as per care instructions to avoid shrinkage.

- For comfort, line both front and back panels, especially in areas prone to transparency or irritation.

- Use power mesh or power net in areas requiring extra support like bust or tummy.

- Avoid excessive seam bulk by carefully aligning lining and outer fabric.

- Consider flatlock seams for a smooth finish that reduces chafing.

Modern swimwear fabrics are evolving with technology to meet the demands of athletes and fashion-conscious consumers alike. Innovations include:

- Chlorine-Resistant Treatments: Some linings are treated with special finishes that extend fabric life in chlorinated pools.

- Moisture-Wicking Properties: Advanced linings pull moisture away from the skin, keeping swimmers dry and comfortable.

- Antimicrobial Finishes: These reduce odor and bacterial growth, improving hygiene.

- Compression Linings: Designed to improve muscle support and reduce fatigue during swimming or water sports.

- Eco-Friendly Materials: Recycled nylon and polyester linings reduce environmental impact without compromising performance.

Incorporating these features can elevate swimwear products, making them attractive to both competitive swimmers and everyday users.

Choosing the right fabric for swimwear lining is fundamental to producing high-quality swimwear that offers comfort, durability, and style. Nylon-spandex and polyester-spandex blends dominate the market due to their excellent stretch, quick-drying properties, and resistance to chlorine and UV rays. Mesh linings add support where needed, and power net linings provide structural reinforcement. For OEM swimwear manufacturers serving international brands, understanding these fabric options and their applications ensures garments meet performance expectations and customer satisfaction. Proper sewing techniques and fabric care further extend the life and appeal of swimwear products.

The most common fabrics are nylon-spandex and polyester-spandex blends because they provide excellent stretch, durability, quick drying, and resistance to chlorine and UV rays.

Lining prevents transparency when wet, adds support and structure, enhances comfort by reducing irritation, and increases the swimsuit's durability.

Yes, self-lining uses the same fabric for both layers, which creates a reversible swimsuit and a thicker, more durable garment, though it is usually more expensive.

Power mesh is a lightweight, stretchy mesh fabric used as lining to provide support and shaping, commonly in high-waisted bottoms or control swimsuits.

Use a ballpoint or stretch needle, zigzag or stretch stitches, and finish edges with swimwear elastic. Pre-wash fabrics and sew lining on seams only to maintain stretch and fit.

content is empty!